There is much discussion from councils and community groups about the best performance infill to use in long pile synthetic grass playing fields (namely all codes of football fields). This article seeks to identify the alternate infills and discuss the pros and cons of each.

Sports Clean is the leading independent provider of maintenance and repair services to these types of fields and many other synthetic sporting surfaces and so is uniquely positioned to comment on this much discussed topic.

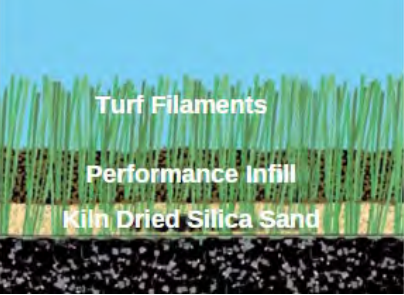

Long Pile Synthetic is typically infilled with 2 materials; beach sand that has been washed (to remove impurities) and then kiln dried, along with what is commonly known as ‘performance infill’, see diagram below.

Typically profile of a Long Pile Synthetic Grass

This article will focus on the performance infill component of a long pile synthetic grass field system.

Sports Clean frequently sees infill used in long pile fields that has not been considered beyond the first application and therefore recommends that the following points be considered when choosing the infill type of a long pile synthetic grass playing field.

- Cost

- Availability of infill for necessary replenishment during the field’s life

- Environmental considerations

- Type of drainage system the field will have.

- Infill containment strategies that are being deployed

Types of Performance infill available broadly fit into 3 categories all of which meet the ‘performance’ required:

- SBR – Recycled black rubber granules, also known as ELT (end of life tyres)

- Manufactured for purpose rubber granules also known as virgin rubber (EPDM, TPV)

- Natural Infills (Cork, wood chip, and occasionally coconut)

SBR Rubber

Image: Infill SBR

SBR rubber is produced by repurposing tyres, is the most cost effective and readily available performance infill which provides some positive environmental results in that it enables the repurposing of tyres which would otherwise occupy a large volume of landfill space. SBR rubber is in use in many community areas such as playground Softfall, and footpaths.

| Positives | Negatives |

|

|

Manufactured for Purpose (Virgin) Rubber

Image: Infill EPDM

Whilst their composition varies (EPDM, TPV) this type of infill is rubber granules that has been newly manufactured for purpose. The granules are produced in many colours and can be found as infill on fields, on athletics tracks, and in softfall in playgrounds.

| Positives | Negatives |

|

|

Natural Infills

Image: Infill Cork

Sports Clean has worked with cork, coconut husk and wood chip, all of these infills have slightly different properties, below is a summary of the most common of these infills, cork and wood particle.

Wood Particles

| Positives | Negatives | Unknown – new to the Australian Market |

|

|

|

Table – Wood Particle infill: positives and negatives

Cork

| Positives | Negatives |

|

|

Table – Cork infill: positives and negatives

Image - Floating cork

General Information

Understandably, corporate social responsibly sees organisations wanting to use products that are sensitive to any number of criteria; environmental, Australian, anti-slavery and so on. These criteria can make the decision around which infill to use a difficult one. Provided below is some information related to the frequently voiced concerns around various infills.

- Microplastic contamination of the environment: this is a risk with any man-made infill and containment controls should be put in place regardless of the type of performance infill used. For perspective, all plastic pellets represent a 0.3% contribution to ocean microplastics.

Chart – Where do the Oceans Microplastics come from

Chart – Where do the Oceans Microplastics come from

Containment controls include raised curbing or a physical barrier at perimeter of the field, walk off matts to capture the granules on shoes, adequate drainage to cope with heavy downpours, sieves in drainage surrounding the field to capture any granules that make it to the drain, and paths that slope towards the field.

- Odour/Chemical composition of SBR: the SBR used in fields should be tested to meet a toxicology & PAH requirement. This is typically enforced by the sporting bodies field certification process; the results of this test should be available from your SBR supplier. There is some belief that only European SBR meets this standard, however there are a number of Australian SBR granule providers who have this certification.

- Heat: Heat is a reality of this product and of synthetic turf systems generally, there is much work being undertaken to improve the heat of these surfaces which will benefit all the heat properties of all infills

- Australian: None of the infills are truly locally made, however tyres are certainly repurposed in Australia to produce SBR (if you use the correct supplier)

- Ballast: The infill in synthetic grass has a secondary duty which is to provide ballast to keep the ‘carpet’ in place. Typically, the natural infills are not as dense or heavy. If the carpet is not adequately weighted it can result in movement, wobbly lines, split seams, fibre breakages and ultimately damage to the field.

- Infill Top Ups: Regardless of the infill chosen budgeting must allow for an infill top up at least once, possibly twice in the life of the field. A ballpark amount for budgeting purposes is 10 Tonnes every 3 years.

In summary, deciding on the most appropriate infill for your surface can be difficult, however ensuring that the needs of the community and the needs of surface are considered and in the budget for the entire life of the field will set you up well to maximise the investment.

About Sports Clean

Sports Clean, started in 1999 was born out of the need to provide a maintenance solution to the explosion of synthetic grass sporting surfaces in Australia. Over time, Sports Clean has continued to improve on the processes and machinery that maximise the life span of a range of synthetic sports surfaces; rubberised athletics tracks, synthetic grass, and acrylic hard court surfaces.

Contact us to discuss your Facility needs

Phone:

E: info@sportsclean.com.au

W: www.sportsclean.com.au

Page updated May 2024